By utilising a removable 100% sealed waste tank the Griffin cabin can stay on site with only the waste tank exchanged for service, creating simple loading / lashing vessel and dockside logistics.

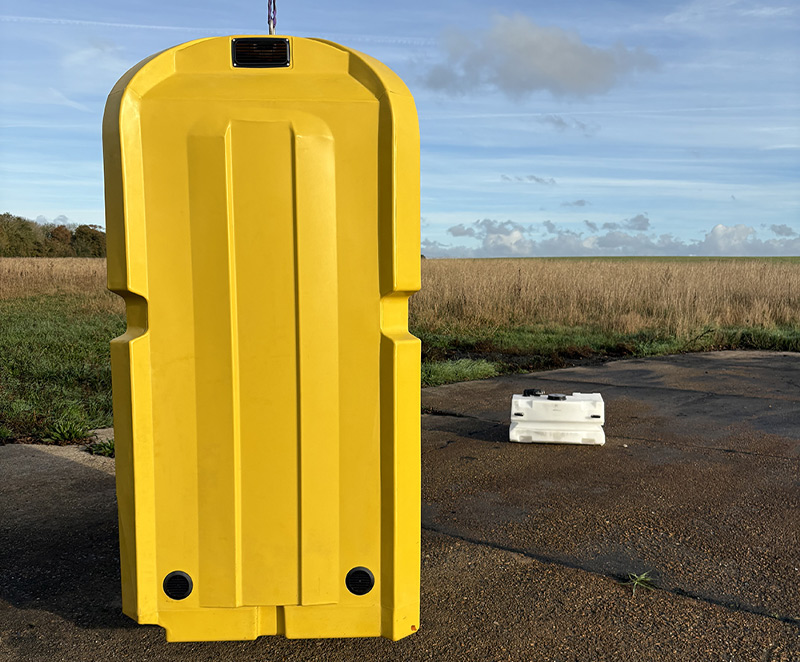

Completely sealed from the interior, the waste tank is accessed from the rear of the cabin via a service door. The tank substantially reduces the cabin’s SWL where manual positioning may be required

An 87-litre tank is the industry's only DIN 16194 compliant, removable option of this size. Made from clear HDPE, the fill level is easily visible from a moulded 87-liter indicator line.

For convenience, remote tank level monitoring is also available.

A leak proof pressure relief diaphragm valve controls venting to stop continuous emission of any effluent smell. Any necessary tank air expansion is released in the rear compartment, not the cabin.

¼ way in from ends around the tank’s circumference secures lifting strops in optimal position for slinging the tank.

Reducing transfers for comfort breaks through fewer ladder climbsand crew transfers delivers an additional safety impact, a key target during construction phases.

Time saved through shorter duration comfort breaks optimises offshore working time.

Crew Transfer Vessels (CTVs) burn significant fuel maintaining position near turbines for technician ladder climbs. With each CTV responsible for up to 12 technicians across multiple, widely dispersed turbines, immediate response times are often unrealistic. Reducing transfers to these vessels reduces fuel, and in turn, helps increase revenue.

“The offshore renewables industry is united in its call for improved wages, better working conditions, and a robust HSE environment to ensure employee well-being and retention.”

Griffin Special Projects Ltd

Beacon Innovation centre, Beacon Park, Gorleston, Great Yarmouth, NR31 7RA